The Of Bayside Laser

Table of ContentsThings about Bayside LaserHow Bayside Laser can Save You Time, Stress, and Money.Bayside Laser - The FactsOur Bayside Laser PDFsThe Best Strategy To Use For Bayside LaserSome Known Questions About Bayside Laser.

Flying optic devices need to utilize some approach to consider the transforming beam of light size from the near area (close to the resonator) reducing to the much area (away from the resonator) cutting. Typical approaches for controlling this include collimation, flexible optics, or making use of a consistent beam length axis.

The power consumption and also performance of any kind of specific laser will certainly differ relying on output power and running parameters. This will certainly depend on the kind of laser and exactly how well the laser is matched to the operate at hand. The amount of laser cutting power called for, referred to as warm input, for a specific work relies on the product kind, thickness, procedure (reactive/inert) utilized, and desired reducing price.

About Bayside Laser

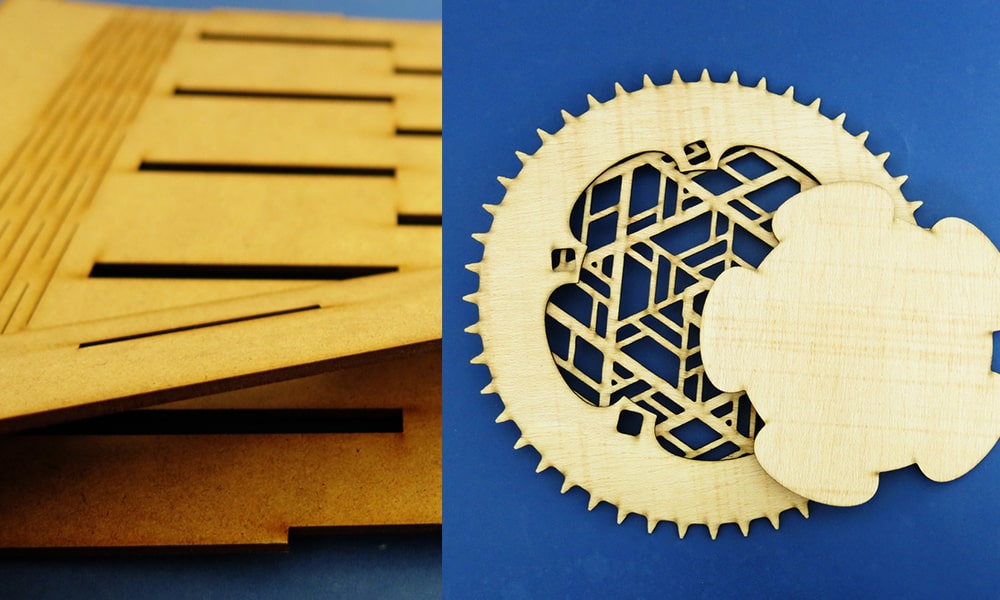

Making use of computerised systems allows for accurate and complex shapes that would certainly have been impossible with standard cutting (laser cutting near me). The individual can conveniently manage the cut's deepness by readjusting the laser beam of light's power as well as emphasis. Laser cutting is regular in steel, wood, plastics and materials. Yet it also has applications for engraving, etching and also marking.

Whether you're trying to find a new or updating your processes, laser cutting has large applications, especially in production. That claimed, below are 4 benefits of laser cutting: Laser reducing is just one of one of the most sophisticated, precise and also accurate techniques for cutting materials. It can provide a degree of information and also accuracy that hand tools can never ever get to.

See This Report about Bayside Laser

The capacity for laser cutting appears virtually limitless as it offers services high-quality typical outcomes in a fraction of the moment. Laser-cutting modern technology is flexible and suitable with numerous products, varying from wood and natural leather to even more difficult-to-cut steels. For these harder-to-cut materials, laser cutters produce perfect accuracy cuts that are not readily available with traditional cutting devices.

Laser-cutting devices are as straightforward as the majority of devices goes. Still, right here are 4 suggestions to look at here now aid get the most out of your procedure: With laser cutting, choosing the suitable material for the task is vital. Depending upon the designated application, different materials may be much more ideal than others depending on variables such as toughness and safety.

Bayside Laser for Beginners

Certainly, laser cutting is a lot faster than the standard approach of cutting steel, yet is it quicker than other modern techniques? Laser reducing beats thermal reducing methods such as plasma or fire in speed when reducing metal of up to 10mm thick.

For those that need to reduce great deals of various forms, laser cutting is absolutely one of the most eye-catching metal cutting alternative. With this method of reducing metal, you do not require to alter devices to make different cuts as the precise same arrangement will perform multiple cutting work as long as the density remains the same.

During the laser cutting process, the light beam made use of does not actually need to touch the material that is being reduced, causing less threat of damage. This means that you will not need to incur pricey repair services or delayed completion times as you might with other techniques of reducing steel - cnc cutting service.

4 Simple Techniques For Bayside Laser

Laser reducing needs much less power than various other techniques, utilizing on average 10k, W of power contrasted to 50k, W for various other reducing procedures. Obviously, the safety and security of your employees is always at the leading edge of your mind and also laser cutting provides among the best methods of reducing steel.

That accurate point develops a very high intensity that can cut via the material. Compared to typical cutting approaches, laser cutting deals a number of advantages.

Unlike lots of manufacturing makers, laser cutters generally do not require you to switch out different devices for whatever cut you want (https://www.pageorama.com/?p=ba7sid3laser). The wonderful point concerning laser reducing devices is that they can work within the very same setup while offering various cutting alternatives. Laser cuttings supply severe accuracy contrasted to various other standard reducing methods.

What Does Bayside Laser Do?

Relying on exactly how a laser cutter is established, you're often mosting likely to observe perhaps a little burr on a component. Normally, it's not needed to eliminate the burr, but it depends on the product, its density and also various other factors. Oh yes, this is just one of the finest components of utilizing a laser cutter; adaptability.

A very narrow section of material is conveniently browsed by the high-powered laser and is really seldom deformed or distorted. Lasers have the capability to cut stainless steel, aluminum, copper, and also brass.